Creating a More Secure Tomorrow: The Advancement of Safety Mesh Solutions

In recent years, the construction industry has seen notable advancements in safety systems, with safety netting emerging as a vital component in ensuring worker safety on job sites. As construction projects grow in scale and complexity, the hazards associated with falls and accidents also rise. Safety netting not only acts as a safety barrier to stop falls from elevated surfaces but also boosts overall site safety by safeguarding tools and materials, resulting in leading to enhanced productivity at work.

Comprehending what safety netting is and its importance in modern job sites is necessary for construction managers, workers, and safety practitioners alike. https://telegra.ph/The-Unseen-Protection-Net-Protecting-At-risk-Populations-01-26 will examine the advancement of safety netting technologies, provide a thorough guide to various types of safety netting, and discuss common mistakes to avoid. We will also cover the regulatory landscape surrounding safety netting, look into the optimal procedures for installation and maintenance, and emphasize how these innovations are creating a safer future for construction and infrastructure projects.

Grasping Safety Mesh Systems

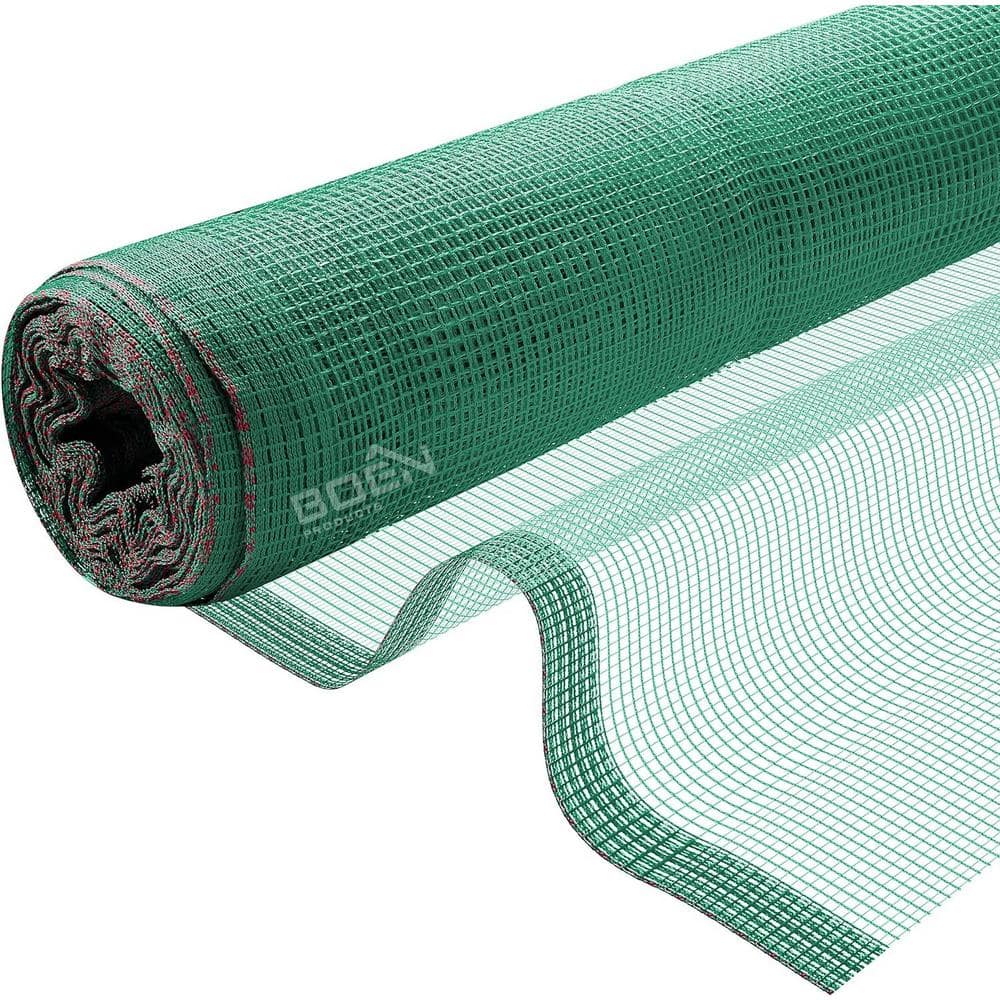

Protective netting is a essential aspect of contemporary construction sites, created to improve employee safety by stopping drops from elevations. This protective system consists of durable net materials that are thoughtfully positioned to stop falling employees or tools, lessening the risks associated with high work. The application of protective netting has progressed greatly over the decades, becoming an essential part of all-encompassing fall safety systems that concern both employee and public security concerns.

One of the main reasons protective netting is important is its capability to provide a trustworthy security barrier that works in conjunction with other safety systems like safety rails. Unlike safety rails that serve chiefly as a physical barrier, safety nets can expand over large work areas, offering coverage that is particularly vital in settings where traditional safety rails may not be possible. This flexibility promotes a more secure working setting, allowing construction tasks to proceed with lessened concern about falls.

In addition to its safety qualities, safety netting plays a vital role in meeting legal requirements, such as those required by OSHA. Proper installation and care of safety netting not only protect employees from unexpected falls but also help contractors avoid legal liabilities. Understanding how safety netting functions and its significance within the broader context of construction site security is essential for contractors, workers, and construction managers aiming to foster a climate of security in the construction sector.

Implementation of Safety Netting Deployment

Deploying safety netting at job sites involves careful planning and conformance to safety standards. To begin with, it is crucial to assess the distinct needs of the operation, which include the type of work being performed and the level of fall risk involved. This assessment will guide the determination of the suitable safety netting variety, considering factors such as load ratings, installation locations, and environmental conditions. Proper risk assessment ensures that safety netting is effectively integrated into the overall safety plan, enhancing worker protection.

Once the appropriate type of safety netting is chosen, the installation method must follow industry standards to ensure maximum protection. This entails fastening the nets securely to the structures, ensuring they are taut and free from hazards. It’s vital to ensure that all personnel participating in the installation are adequately trained and comprehend the safety protocols. Regular inspections during the installation stage can help detect potential issues promptly, allowing for swift corrections and reinforcing the importance of safety in all aspects of the project.

Continuous maintenance and compliance checks are vital for the ongoing effectiveness of safety netting. After installation, routine inspections should be conducted to assess the condition of the netting, checking for damage and any damage caused by environmental factors or construction activities. Documenting these inspections not only ensures conformity with regulations but also provides important insights for upcoming projects. By emphasizing https://queenheat2.werite.net/five-safety-netting-options-for-enhanced-workplace-environment-security and maintenance, contractors can significantly enhance worker safety and reduce liability in construction sites.

Future of Safety Netting Technologies

The future of protective netting systems is poised for substantial advancements propelled by innovation and need for better worker protection. As construction projects are more complex and the necessity for strong safety measures intensifies, manufacturers are investigating new materials that offer increased durability and flexibility. These developments aim to create nets that can endure varied environmental conditions while maintaining their structural integrity, ensuring that they provide maximum safety on construction sites.

Incorporation with intelligent technology is another hopeful trend. As the construction industry more and more adopts digital solutions, safety netting can gain advantages from advanced features. For instance, nets fitted with sensors could observe load limits and environmental conditions in real-time, alerting site managers to potential risks. This proactive approach to safety netting not only enhances protection but also simplifies compliance with safety regulations, providing a more thorough safety net for workers.

Looking ahead, eco-friendliness will become an integral focus in the advancement of safety netting technologies. Sustainable materials and production processes are likely to take center stage, as the industry seeks to lessen its environmental footprint. By prioritizing eco-conscious practices, companies can not only improve their brand image but also contribute to a safer and more sustainable future in construction, ensuring that safety netting evolves in tandem with broader industry standards and societal expectations.